Talk to us

08045478750

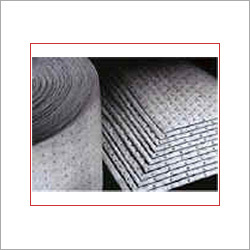

By keeping track with the market development, we are supplying the excellent quality Absorbent Pads and rolls, which are favorable for industrial applications. These are great for water & oil based liquids and excellent for machine, maintenance shops, industrial plants, etc. We ensure these pads soak up more liquids in less time, as they have high absorbency, superior strength and are excellent in performance. These pads can be used where non-aggressive and aggressive fluids are present. Furthermore, the Absorbent Pads available to us at affordable prices.

Technical Specification

| GSM | 400 |

| Thickness | 2 mm - 5 mm |

| Container Type | Box |

| Usage/Application | Industrial |

Price:

Style : Pad Mat

Used For : Absorbing hazardous chemicals and fluids

Application : Chemical spill containment, industrial cleanup

Capacity : Absorbs up to 20 times its own weight

Operating Temperature : 20C to 80C

Features : Highly absorbent, tearresistant, safe for oil and acid spills, quick wicking

Style : RopeEnclosed Tubular Boom

Used For : Absorbing and Containing Oil Spills on Water

Application : Oil Spill Control, Spill Containment

Capacity : High Oil Retention per Meter

Operating Temperature : 30C to 70C

Features : UV Resistant, Easy to Deploy, Linkable, Snap Hooks Attached

Style : Flat Pad

Used For : Absorbing Oil, Fuels, Hydrocarbons

Application : Oil Spill & Leak Cleanup

Capacity : Up to 1.2 Liters per Pad

Operating Temperature : 20C to 70C

Features : Lightweight, High Absorption, Easy Disposal, LintFree

Style : Boom

Used For : Hazmat spill response and cleanup

Application : Containment and absorption of hazardous chemical spills

Capacity : Up to 4 gallons per boom (varies by size)

Operating Temperature : 20C to 60C

Features : Durable, flexible, quickdeploy, chemical resistant